Anjing Road, Xiaolan, Zhongshan, Guangdong, China

info@mes-drive.com

08.00 AM-09.00 PM

On the morning of October 12th, 2025, crowds gathered in downtown Seattle to witness the inaugural commercial flight of a new generation of electric vertical‑takeoff and landing aircraft—eVTOLs. The aircraft, a sleek, four‑propeller design from start‑up SkyRoute, hovered above the city, then descended gracefully into a clear glass parking area, leaving a lingering sense of awe and a buzz that quickly spread across social media. Within hours, headlines were flooded: “The Future of Air Travel: First Commercial eVTOL Flights Sign On,” and “Cities Sound the Alarm on the Massive Growth of Urban Air Mobility.”

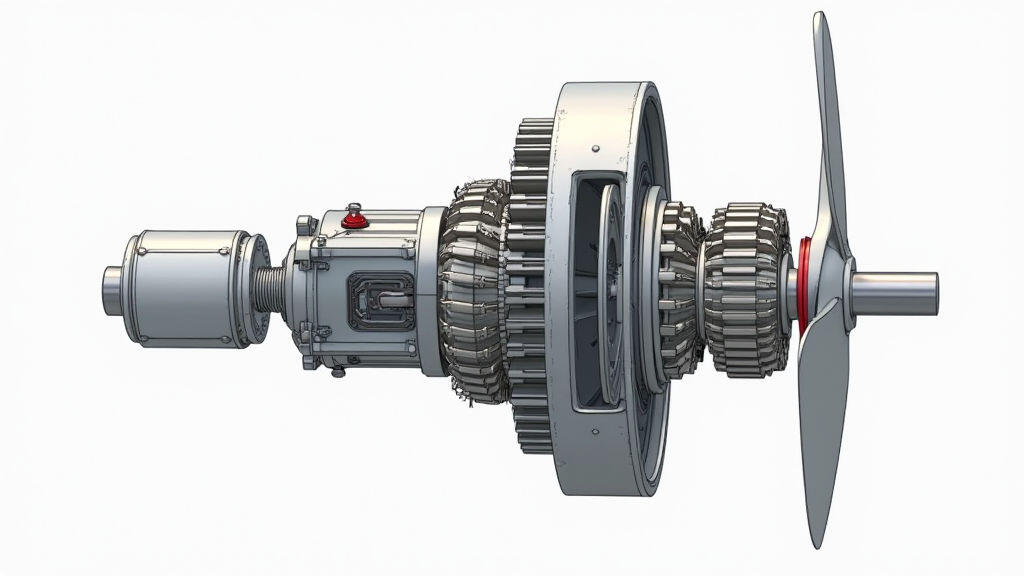

The event marks more than a milestone in aviation; it signals a seismic shift toward sustainable, efficient transportation that relies on cutting‑edge components—one of the most critical being the gear motor, or reducer motor. While the world watches eVTOLs take to the skies, it’s the unseen gears powering them that keep the revolution grounded—quite literally.

eVTOLs hinge on electric propulsion systems, meaning every kilogram of weight and every watt of energy directly affects flight time, range, and payload capacity. Gear motors condense the pure energy of a powerful electric motor into a controlled, higher‑torque output that the aircraft’s rotors can use efficiently.

1. Torque Conversion & Efficiency

A standard electric motor delivers a high rotational speed but relatively low torque. By integrating a gear motor, designers lower the speed while increasing torque—an essential function for turning the motor’s shaft into the thrust needed for lift and forward flight. This conversion allows for smaller, lighter motors, directly translating to lighter aircraft and longer flight durations.

2. Weight and Size Constraints

eVTOL manufacturers strive for ultra‑light kits; every gram counts. Gear motors are engineered for compactness and minimal mass while maintaining a high power‑to‑weight ratio. This makes them ideal for the strict weight budgets of emerging eVTOL platforms.

3. Reliability & Durability

Urban air mobility demands unsurpassed reliability. Gear motors equipped with precision‑machined gears endure repetitive thrust cycles and can handle substantial load variations without a drop in performance—an essential attribute for commercial operations and safety regulation compliance.

The eVTOL market is not just emerging; it’s expanding at a compounded rate that outpaces many traditional aviation sectors. By 2030, analysts predict the fleet could grow to over 30,000 aircraft serving global urban corridors.

Plug‑in Shift to Electrification

Governments worldwide are mandating greener transportation: the European Union’s “Clean Sky” directive, the United States’ electric vehicle tax incentives, and China’s new EV road regulations are just a few examples. The eVTOL industry, leaping forward under these policies, requires robust gear motors to meet strict performance standards while staying within cost limits.

Supply Chain Development

Established automotive and industrial motor manufacturers are diversifying into the electric aviation estate. This diversification introduces competition, triggers price reductions, and accelerates the development of specialized gear motor solutions optimized for aviation purposes—packaging, noise reduction, and thermal management.

In the evolutionary path of eVTOLs—from helium‑filled balloons to heavy turbines—gear motors represent a technological gatekeeper.

Prototyping and Rapid Iteration

Design cycles for new eVTOL concepts are increasingly short. A modular gear motor meets this demand, enabling designers to swap out motor assemblies during prototyping without redesigning the entire propulsion system.

Integration with Smart Systems

Modern eVTOLs incorporate fly‑by‑wire controls, battery management systems, and AI‑based flight planning. Gear motors feature electronic speed controls (ESCs) and sensor outputs, allowing them to integrate seamlessly with these digital ecosystems, thus enabling real‑time torque management and predictive maintenance.

Sustainable Manufacturing

The gear motor’s production processes favor additive manufacturing and high‑grade composites, reducing material waste and energy consumption. This sustainability aligns with the very ethos many eVTOL companies aspire to, further boosting the gear motor’s appeal.

SkyRoute’s newly unveiled 12‑passenger eVTOL, the SkyFlyer 12, uses a lightweight, high‑torque gear motor across each of its four rotor hubs. The motors derive power from a 250‑kWh lithium‑carbon battery pack, delivering an impressive 35‑minute flight time on typical urban routes.

Engineers highlighted that each gear motor’s torque provides a 3‑fold increase over a conventional motor of the same size, allowing a smaller stator and fewer cooling fans—half the weight, half the volume. The result? A significant lift‑to‑weight ratio, facilitating a 3,000‑kilogram maximum take‑off weight while keeping the silhouette minimal.

Looking ahead, the synergy between emerging eVTOL technologies and gear motor advancements promises a cascade of benefits:

As urban landscapes grow denser, cities worldwide aim to incorporate vertical take‑off flight into public transit solutions—air‑taxis, cargo drones, and emergency services. The gear motor, though often overlooked, will be the steadfast partner that turns electric pulse into lift.

The eVTOL event of October 2025 has ignited a worldwide conversation about the future of air travel, but the real story behind the buzz is the mechanical ingenuity of gear motors. By converting electric power into precise, high‑torque output, these reducers enable aircraft that are lighter, safer, and more efficient.

With soaring demand and relentless innovation, the gear motor is poised to play a cornerstone role in the next era of sustainable, urban mobility—bringing the sky literally closer to the people beneath it.

Future developments in gear motor technologies—through advanced materials, smarter controls, and tighter manufacturing tolerances—will directly influence how fast, how far, and how many eVTOLs can soar. Thus, while the headlines may celebrate the pilot’s first flight, it is the gear motor that will keep society’s dreams of airborne commutes grounded in reality.

Leave A Reply

Your email address will not be published. Required fiels are marked