Anjing Road, Xiaolan, Zhongshan, Guangdong, China

info@mes-drive.com

08.00 AM-09.00 PM

When the International Energy Agency (IEA) released its “Global EV Outlook 2025” last month, the headline was unmistakable: electrification of transport is no longer a trend—it’s a global necessity. The report projected that by 2030, electric vehicles (EVs) will account for 60 % of all new car sales, and freight trucks could see electrified fleets reaching 25 % of all commercial vehicle sales. This shift has sparked a wave of technological innovation across the automotive sector, bringing gear motors—specifically reducer motors—into the spotlight as key enablers of efficient, high‑performance EV powertrains.

For many years, EV technology seemed to revolve around batteries and zero‑emission power. Manufacturers and consumers rang up the electric buzzwords, but the practical rollout required more than just a rechargeable pack. Reliable, compact gear motors were a missing puzzle piece. They serve as the mechanical bridge between the electric motor and the vehicle’s wheels, controlling speed and torque while keeping a vehicle’s weight and footprint low. With the IEA’s predictions, automotive companies are now investing heavily in next‑generation gear motors that can deliver higher torque densities, lower losses, and improved durability—all critical for meeting the performance expectations of modern EVs.

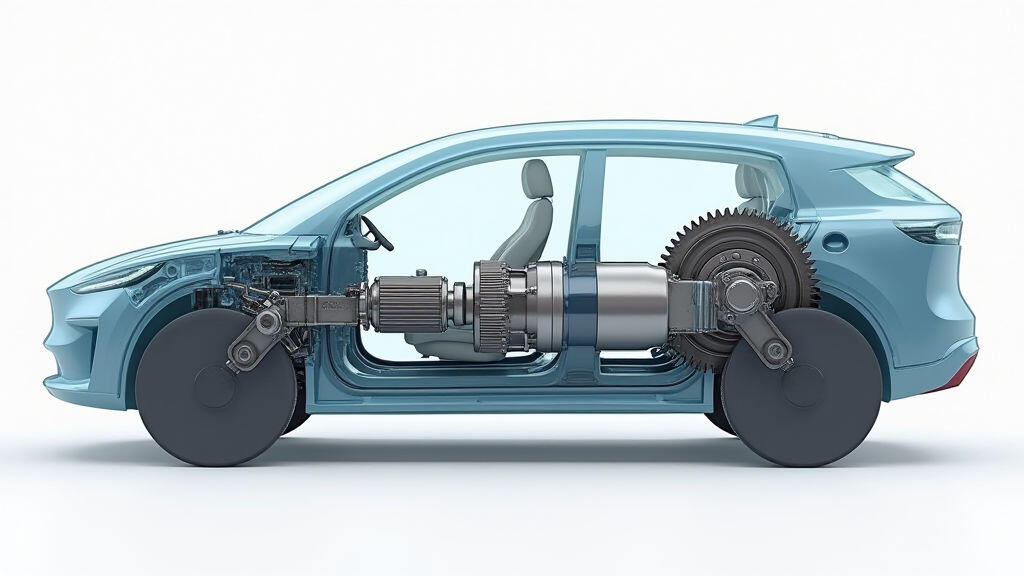

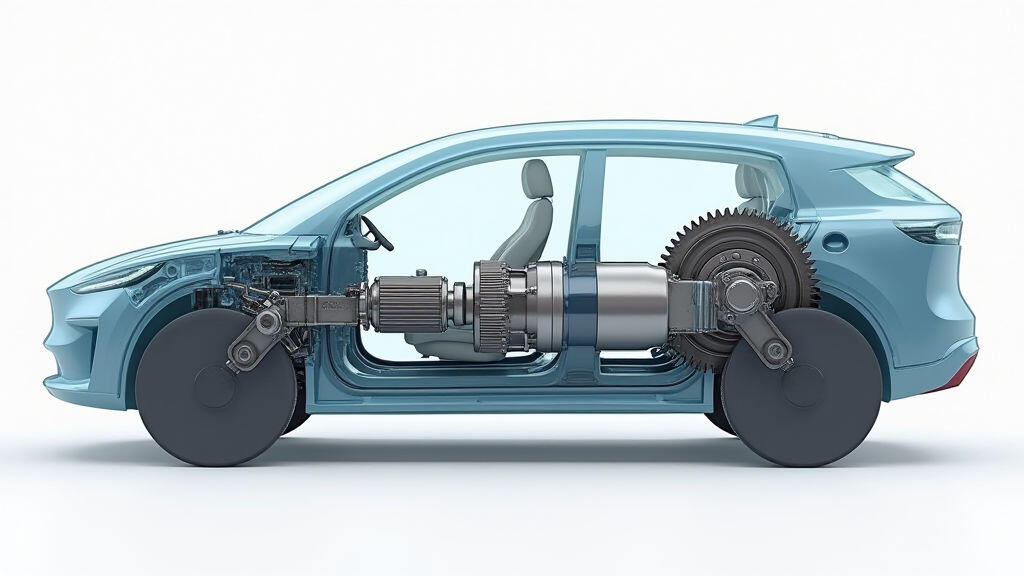

The typical EV drivetrain consists of an electric motor, a gearbox or reducer, and the wheel assembly. The gear reducer—often a planetary or helical design—is where the gear motor’s role becomes decisive. It reduces the high‑speed, low‑torque output of the motor to a useful rotation for the wheels while multiplying torque for rapid acceleration. The biggest challenge in this relocation is how to keep the entire unit as compact and energy‑efficient as possible.

Recent progress in gear motor design, especially in high‑speed miniature dimonial gears and lightweight alloy housings, directly addresses these challenges. By integrating the gear motor into the motor housing, manufacturers can reduce the number of separate components, simplify assembly, and lower total vehicle mass. Lighter vehicles directly translate into extended battery range, a vital metric in the consumer’s decision process.

Furthermore, new materials such as ceramic‑reinforced composites and advanced surface coatings reduce wear, allowing gear motors to operate at high temperatures without compromising performance. This improvement is essential for all‑electric trucks that must bear heavier loads and endure harsher operating conditions than passenger cars. Gear motors that can sustain high torque densities for months or years—without significant losses—provide a competitive advantage for manufacturers aiming to capture the electrified freight market.

The surge in electric vehicle adoption places raw material and component supply chains under increased pressure. The demand for high‑quality gear motors is a micro‑tale of broader supply chain acceleration. To meet the 2030 EV targets, automakers must secure more gear motors than any single industry could supply on its own. This market dynamic encourages partnerships between automotive OEMs and component suppliers—many of whom are already investing in new production lines for gear motor manufacturing.

For example, a recent strategic partnership between an EV start‑up and a renowned gear motor manufacturer revealed a joint venture focused exclusively on producing high‑torque reducers for battery trucks. The joint venture is slated to run at a global production capacity that could supply up to 30 % of the projected global EV fleet by 2035. Such collaborations hint at a future where gear motor businesses increasingly become integral players in the automotive ecosystem, rather than peripheral component suppliers.

At its core, gear motor innovation is a story in efficiency: fewer mechanical losses mean more of the battery’s stored energy translates to real motion. Even a 2 % improvement in gearbox efficiency can extend the driving range of an EV by 10 km. That difference can be the deciding factor between a customer choosing an EV over a combustion engine, or between a logistics company deciding on an electrified fleet.

Moreover, the environmental footprint of gear motors themselves is shrinking. Modern manufacturing methods, such as additive manufacturing for gear architectures, allow precision tolerance while reducing material waste. Together, the gear motor’s smaller size and lighter weight decrease overall vehicle mass, leading to lower emissions over the vehicle’s lifetime—fulfilling circular economy principles that governments worldwide increasingly mandate.

In addition to electrification, the automotive world is also looking to a future of autonomy. Autonomous delivery drones, people movers, and warehouses will rely on reduced, high‑torque gear motors to enable smooth, reliable motion under varying load conditions. In smart docks, small industrial robots equipped with gearbox‑powered gear motors can automatically rotate forklifts or cargo pallets, saving time and reducing accident risks. Gear motors appear at the heart of these emerging technologies, providing precision speed control and rapid acceleration essential for complex automation tasks.

The world’s accelerated transition to electric mobility, as measured by the IEA’s bold forecast, has shone a spotlight on every component that can keep the ecosystem running—startlingly, even the humble gear motor. These small, yet powerful, devices now drive the very heart of EVs, from fast‑acceleration sunrise to heavy‑haul midnight deliveries. Their evolution reflects a yearning for higher performance, greater efficiency, and relentless sustainability.

Gone are the days when gear motors were just another part in the machine. Today, they are partners in the global mission to cut emissions, deliver faster service, and enable the endless possibilities of a fully electrified world. As the automotive industry continues to push boundaries, gear motors will remain integral, quietly turning torque into motion and turning dreams into drive.

Leave A Reply

Your email address will not be published. Required fiels are marked